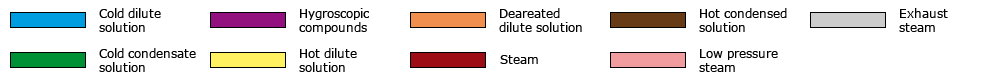

Process

i

Steam turbine: the steam produced in the steam generator moves the blades by rotating the turbine shaft. Thus the energy contained in the steam is converted into mechanical energy of rotation, and then transformed in electrical energy through alternator.

i

Absorber: this equipment put in direct contact the exhaust steam, which has given some of its energy to the turbine, with a concentrated absorbent stream (aqueous phase), which contains hygroscopic compounds that enhance steam condensation.

i

Condensate pump: the diluted solution that comes from the absorber is taken by it, being one part discharged to a deaerator (after passing through the enthalpy recuperator) and another part makes the absorber reflux, previously passing through an air cooler.

i

Air cooler: in this equipment de concentrated solution and absorbent releases the condensing energy of steam by indirect contact of air.

i

Deaerator: it eliminates all bubbles, microbubbles and dissolved gases, particularly oxygen and carbon dioxide from dilute solution that returns to the steam generator.

i

Solution pump: the dilute solution is leaded to steam generator in a high pressure.

i

Steam generator: provides energy, thanks to a hot point, concentrating absorbent solution thus obtaining a clean steam, suitable for turbine.

i

Enthalpy recuperator: the concentrated solution of the return stream of steam generator, gives its thermal energy to the dilute solution stream which come from the absorber, which is leaded to deaerator.

Continue to Profits and applications.